Tearing Resistance Testing tv shopping|rubber tear testing methods : chain store A tearing resistance tester is specifically designed to measure the force required to propagate a tear in a sample material. This measurement is crucial for determining the durability and .

Resultado da The latest tweets from @mucalol

{plog:ftitle_list}

Resultado da 13 de dez. de 2023 · Tempo WindGURU para Guarapari: Temperaturas, chuva, umidade e mapas.

The Elmendorf tear tester measures tearing resistance by calculating the force required to propagate a tear through a material sample. Why should I choose the SLD-01 Tear Tester? .

Tear testing is a mechanical testing procedure used to measure a material’s resistance to tearing. It involves applying a controlled force to a specimen, often with a pre-initiated tear or cut, to evaluate how the material behaves under .Tensile testing tests a fabric’s strength and elongation properties, with two common methods the grab test ASTM D5034 and the strip test ASTM D5035. Tear testing measures the resistance of fabric to tearing using three popular . The Elmendorf tear tester helps manufacturers assess the tear resistance of fabrics used in clothing, such as denim, woven fabrics, and knitted materials. By ensuring optimal tear strength, garment manufacturers can .

This Complete Guide of the Elmendorf Tear Testing explores tear resistance testing dimensions, application areas, standards, methodologies, troubleshooting, and the future landscape of tear analysis. Key takeaways .A tearing resistance tester is specifically designed to measure the force required to propagate a tear in a sample material. This measurement is crucial for determining the durability and . The tear resistance test on fabrics or tear strength is measured to check how the material can withstand the effects of tearing or cuts when in tension. The tear strength is measured as per the ASTM D412 standard test .A: Using higher capacity load cell depends on what results you are trying to achieve. You need to think about how a load cell is calibrated according to ISO 7500, the first point of calibration is .

Tear resistance testing can be found in plastic film, paper and textile industries. Tear resistance is the measurement of a sample’s ability to resist tearing. Tear resistance can be impacted .Tensile, tear, and bursting strength are important parameters for determining a fabric's level of strength. Tear resistance (or tear strength) measures how well a material can withstand .Purpose: This test method is used to determine the average force (grams) to propagate tearing through a plastic film in machine and/or transverse direction. Sample: We usually need about one (1) square foot of plastic film for each test direction. Price & Delivery: Contact us for a quote. Basic Description: An impact tester with a pendulum is used to measure the force (grams) .

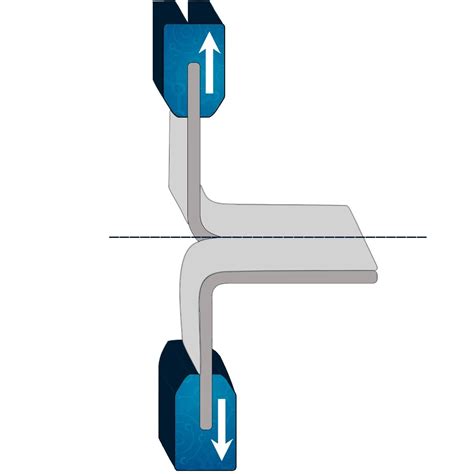

The tearing strength tester is an appropriate tool to measure the tear resistance of various materials including textiles and fabric. Types of tear test: Tongue Test; Trapezoid; Elmendorf; Measurement of fabric tearing .The tear resistance test on fabrics or tear strength is measured to check how the material can withstand the effects of tearing or cuts when in tension. The tear strength is measured as per the ASTM D412 standard test method, which is also used to measure tensile and elongation. The standard test method measures the resistance to the formation .Tearing Resistance: Tearing resistance is one of the important properties of a textile fabric. . Shape of specimens: (a) specimen tearing on a nail; (b) specimen cut in the middle; (c) rectangular – tongue tear test (single tearing); (d) rectangular – tongue tear test (double tearing): (d1) three tongues, (d2) three uncut tongues; (e . One way to measure tear resistance is through the Pendulum Method or Elmendorf Tear Test, as defined by ASTM D1922. The Elmendorf Tear Test is a simple and reliable way to measure the force required to propagate a slit in a plastic film a fixed distance to the edge of the test sample. The test is performed using a pendulum impact tester, which .

Purpose of a tear test: The overall goal of a tear test is to determine a materials ability to resist the growth of the initial tear or its “tear resistance”. The value of a material’s tear resistance is generally accepted to be the force required to complete the tear so that it has gone completely though the material so that it has been .

Application of Tearing Resistance Testing. Tearing resistance testing is crucial across various industries. For example: Packaging: Ensures that packaging materials can withstand the rigors of handling and transportation. Textiles: Assesses the durability of fabrics used in clothing and industrial applications.The tensile strength of a material is the maximum mechanical tension it can withstand before it cracks. It is given in N/mm² or MPa. The tear resistance of a material, also called tensile strength at break, is the mechanical tensile stress at the exact moment of tearing and is also given in N/mm² or MPa.. Since the maximum tensile stress and the tensile stress at the moment of . Reduction of tear resistance as a consequence of defects in soft biological tissues is relevant for a number of medical problems. . Polym. Test. 60, 117–123 (2017).

tear testing techniques

Tear Resistance Test is professional designed for tensile strength, elongation test, peeling test and other physical properties test for flexible materials w. The tearing behavior of materials is a major component of their mechanical performance. In particular, in the case of protective materials, the tearing resistance is generally among the requirements, for example with protective gloves [1] and firefighter protective suits [2], [3].In the research community, large efforts have also been devoted to the understanding of .

ISO 6383-1:2015(E) 8 Number of test specimens 8.1 A minimum of five test specimens shall be tested in each of the required directions of testing. 8.2 Specimens which show a tear out of line to the extent that the tear reaches one of the edges of the test specimen shall be discarded and further specimens tested (see 11.3). 9 Speed of testing

General paper property that takes into account two measures of a paper's ability to withstand being torn. Internal tearing resistance refers to the work required to tear a paper sample through a specified distance once the tear has been started. Edge tearing resistance refers to the work required to tear a paper sample by starting the tear at the edges of the sheet. Fabric tear resistance is crucial for safety, product durability, and customer satisfaction. The Elmendorf test is a standardized method widely used across industries. It helps quantitatively .The SLD-01 Tear Tester offers advanced features like PLC control, wide test range, and automatic data collection, ensuring accurate and consistent tear resistance testing. Why is tear resistance important in packaging materials? Tear resistance in packaging materials ensures that the packaging can protect its contents during transportation and .

ASTM D1004 Tear Resistance This test method covers the determination of the tear resistance of flexible plastic film and sheeting at very low rates of loading, 51 mm (2 in.)/min. and is designed to measure the force to initiate tearing. The specimen geometry of this test method produces a stress concentration in a small areaTearing Strength Tester. Tearing strength testing can be found in plastic film, paper and textile industries. It is used to describe how well a material can withstand the effects of tearing. Elmendorf tear is a common method that is .1.2 It is not suitable for determining the cross-directional tearing resistance of highly directional boards and papers. These materials are covered by TAPPI T 496 “Cross Directional Internal Tearing Resistance of Paperboard.” 1.3 For edge-tear resistance see TAPPI T 470 “Edge Tearing Resistance of Paper (Finch Method).” 2. Summary

The tear resistance is measured as the average force in mN propagating the tear to the edge of the test piece. We are UKAS accredited for testing to British standard BS 2782:3 method 360A. Smithers also test to International standard ISO 6383-2 and ASTM D1922.from Test Method D1004, wherein the specimen is strained at a rate of 50 mm (2 in.) per minute. However, specimen geometry and testing speed of the two test methods are dissimilar.The rate of tearing in this test method, while varying as a function of resistance to tear, is in the range from 7.6 to 46 m (300 to 1800 in.)/min.There are three main standards which describe the fracture toughness testing of ductile alloys by generating tearing resistance curves: BS 7448-4 (1997), ISO 12135 (2016) and ASTM E1820 (2018). Each of these standards differs in significant details relating to the generation and analysis of the test data.ISO 1974 was prepared by Technical Committee ISO/TC 6,Paper, board and pulps, Subcommittee SC 2, Test methods and quality specifications for paper and board. . This International Standard specifies a method for determining the (out-of-plane) tearing resistance of paper. It can also be used for boards having a low grammage if the tearing .

What is Elmendorf Tear Tester?. The Elmendorf Tear Tester is a widely used instrument in material testing. It is specifically designed to measure the tear resistance of various materials, including films, paper, textiles, and non-woven fabrics.This testing method helps in assessing the material’s ability to withstand tearing forces, providing valuable insights into its quality and .

tear resistance testing methods

s7 vs s7 edge drop test

Originally introduced in 1964, ASTM D2261 was most recently updated in 2013 and specifies the method for tear testing of fabrics by the tongue (single rip) procedure to measure the tearing strength of the fabric. This test method applies to most textile fabrics, including those that are treated and untreated, woven, knitted, or unwoven.

The samples were cut in the warp direction. Tear tests consisted in a loading/unloading cycle performed on a MTS-Alliance tensile testing machine at 100 mm/min with various levels of maximum displacement. During the test, the tearing force–displacement curve was recorded. An example of tearing force–displacement curve is shown in Fig. 1.ISO 1974:2012 specifies a method for determining the (out-of-plane) tearing resistance of paper. It can also be used for boards having a low grammage if the tearing resistance is within the range of the instrument. ISO 1974:2012 does not apply to corrugated fibreboard, but it may be applied to the components of such boards.Tear resistance measures the ultimate force required to tear film or sheet. It is often used for quality control checks or for material comparison where tear failures are possible. Test Procedure: The average thickness of the specimen is measured.

s7 vs s8 drop test

tear resistance testing machine

25 de jan. de 2024 · Foto: Reprodução / PORTAL DO ZACARIAS Nesta quarta-feira, 24/01, circula em grupos de WhatsApp um vídeo onde mostra um jovem sendo assassinado com vários golpes de facadas. Segundo informações, a vítima foi identificada como Andres Alberto Sosa, e o autor desse crime covarde é conhecido como vulgo Carcereiro do .

Tearing Resistance Testing tv shopping|rubber tear testing methods